Adhesives are widely used in the electronics industry, from microcircuit positioning to giant generator coil bonding. Once the adhesive fails, the consequences will be very serious, the computer will stop running, the city will be dark, or the missile launch will be difficult.

In addition to mechanical fixation, the application of adhesives in the electronic industry also requires heat conduction, conductivity and insulation to meet the requirements of impact resistance assembly, sealing and protection of substrates. The characteristics required for different applications include: the service life ranges from a few seconds to several years, and the dosage ranges from less than micrograms to more than 1 ton.

1、 Application of various adhesives in electronic industry

1. Epoxy adhesive: it is the most widely used in the electronic industry. It has the advantages of strong versatility, excellent adhesion, wide adaptability, convenient use, good electrical performance, aging resistance, etc.

2. Organic silica gel: suitable for occasions requiring flexibility, wide temperature range, high frequency, high temperature and air pollution.

3. Hot melt adhesive: the hot melt adhesive can be used under the conditions of rapid assembly, low strength and low working temperature.

4. Acrylate adhesive: the selection of acrylate adhesive mainly considers that it has excellent electrical properties, stability, good aging resistance and transparency, and can cure rapidly.

5. Polyurethane adhesive: keep soft, tough and firm from low temperature to 121 ℃.

6. Precoated polyvinyl butyral: it can form a tough and easy to assemble joint.

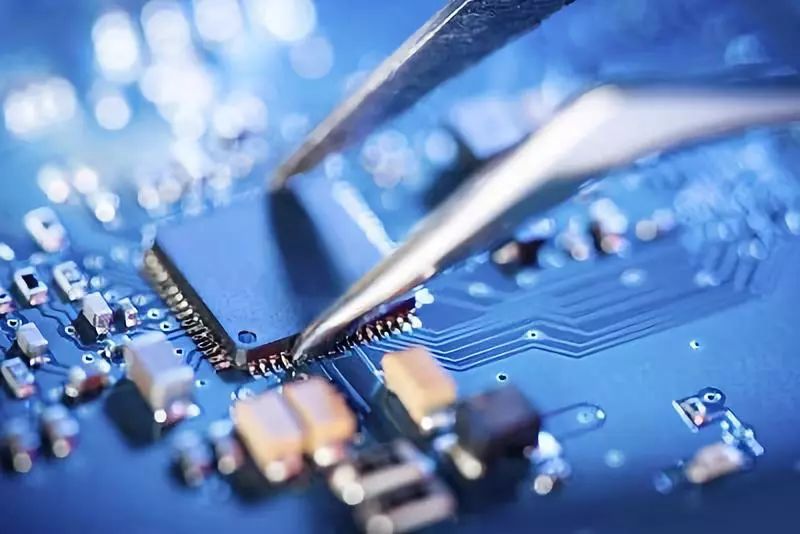

2、 Three main applications of adhesives in Microelectronics

1. Pipe core bonding;

2. Bonding between circuit elements and substrate;

3. packaging. Another major application is printed circuit boards. Since the welding temperature must be 250 ℃, the adhesive is limited to the bonding between the steel foil and the laminated printed circuit board.

4、 Application of adhesive in large equipment

For example, generators, transformers and other equipment operating under high temperature, as well as equipment that must operate under harsh environment and high temperature conditions for 20-40 years. The size of many devices precludes the possibility of oven curing. The heat conduction of copper and other metals makes local heating impossible. Therefore, room temperature curing adhesive must be used.

5、 Application of adhesive in electronic equipment

Adhesive applications can be found in almost all electronic equipment, such as the bonding of radar antenna composites, which provides heat conduction and conductivity for the work of electronic components. And the bonding of the front cone ring of the missile. Typical applications include:

(1) Antenna reflector for tracking / illuminating radar in ship air defense system;

(2) Cobra Daye phased array radar system for bonding external dielectric window to substrate;

(3) Drill various electronic components of Trident MKS missile guidance computer with thermal conductive adhesive film;

(4) In the air traffic command radar, the cured epoxy laminate is bonded to the metal frame.

5、 Application of adhesive in printed circuit board

Printed circuit boards, whether rigid or flexible, are inseparable from adhesives.

For epoxy glass plate, acetal phenolic, nitrile phenolic or modified epoxy can be used, and the maximum service temperature is about 150 ° C. When used at high temperature of 260 ° C, glass silicone laminate or copper / polytetrafluoroethylene composite plate shall be used.

Laminated components of rigid printed circuit boards can be bonded together with plastic films coated with thermoplastic or thermosetting adhesives.

Sometimes complex components require thin and flexible printed circuits. At this time, RTV silicone rubber coating can not only be used as insulation coating, but also reduce vibration, which will increase unnecessary fatigue load on welded joints.

In addition, the stressed parts are coated with epoxy adhesive and organic silica gel to reduce impact and vibration.