Industries around the world are catching up with the improvement of modern structural tape. Because of its various uses, structural bonding technology has replaced the traditional assembly methods, such as riveting and welding. Nowadays, almost every consumer product has oneortwo kinds of structural adhesives. Throughout, structural adhesives have been helping some of the most innovative and mature OEMs simplify their product lines and maximize process efficiency and finished product quality.

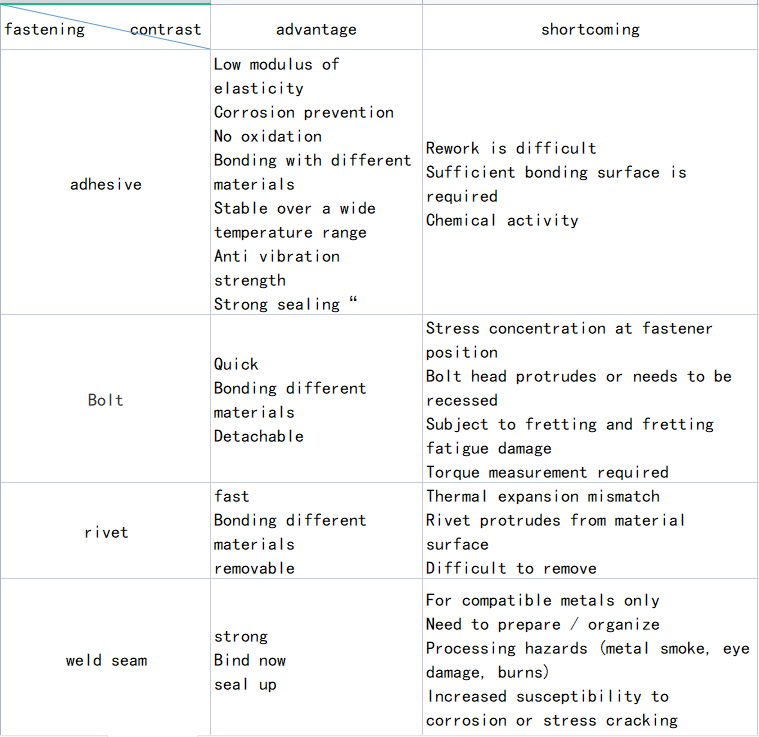

Structural adhesive is not only applicable to almost all parts, but also stronger and more reliable than mechanical fasteners such as bolts, rivets and welding. Adhesive has many advantages and few disadvantages. It is an excellent choice for many manufacturers.

Three types of adhesives are commonly used in structural bonding applications: epoxy, acrylic, and polyurethane. The choice of adhesive depends on the material to be bonded, the operating environment and the process specification.

Compared with traditional connection methods, structural adhesive has excellent advantages in cost, production efficiency, light weight and performance. In most production applications, structural adhesives can provide higher strength and longer service life for components. Compared with traditional rivets and welding, structural adhesives eliminate the costs associated with metal preparation and finishing operations, thereby improving the efficiency of the manufacturing process.